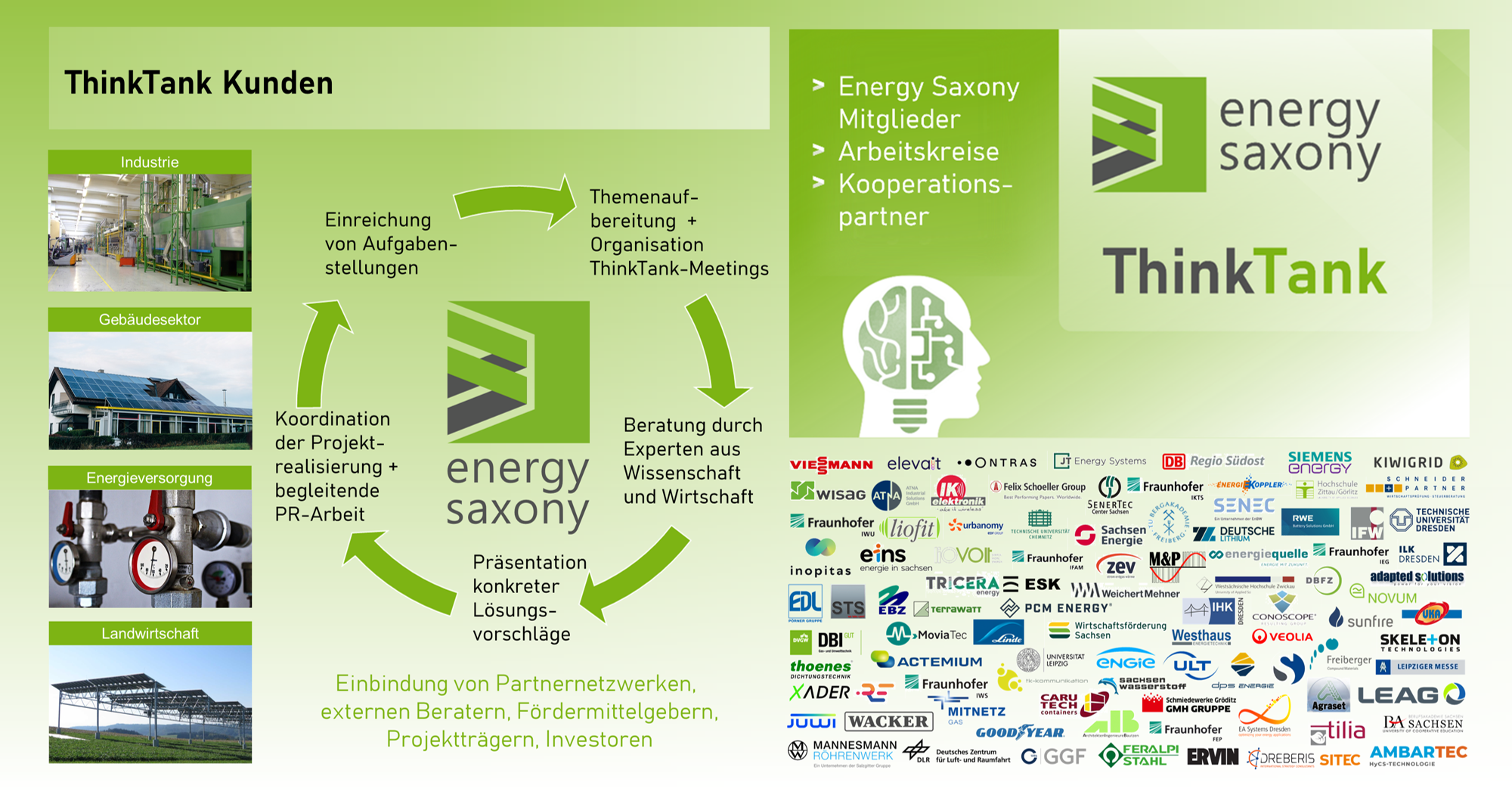

Energy Saxony offers its ThinkTank customers technology and funding consulting organized as a think tank, networking with experts from science and industry, and centrally coordinated project management.

In the ENERGY SAXONY ThinkTank, experts from science and business come together to work on joint projects for customers from industry, the real estate sector, energy supply and grid operators, as well as from municipal administration and agriculture to develop sustainable, resource- and climate-friendly solutions for the green transformation of the economy. The overarching goal is to secure an affordable and environmentally friendly energy supply as the basis for a strong, internationally competitive Saxon economy, the reduction of emissions and resource consumption, as well as a new product design and conversion of value chains according to the principle of the circular economy in concrete applications. In order to better align supply and demand and thus leverage cost-saving potential and create synergies, the potential of digitalization for the intelligent control of energy and material flows is also to be leveraged.

Do you have a challenging task for the ENERGY SAXONY ThinkTank? Please send us an email to thinktank@energy-saxony.net with a short presentation about your company and your goals, which should be implemented with technological solutions. We are looking forward to your enquiries!

The ENERGY SAXONY ThinkTank sees itself as an open think tank, where basically all stakeholders can contribute with ideas and solution proposals. The established cooperative relationships with other clusters, such as Biosaxony e. V., Silicon Saxony e. V., buildingSMART Deutschland e. V., Cluster IT-Mitteldeutschland e. V., VEE Sachsen e. V., Smart Systems Hub, VEMASinnovativ or the BDEW (list of ENERGY SAXONY partners), thus also enables the option of consulting cross-industry expertise in the solution of concrete technical problems. As customers, all full members of the Energy Saxony network can use the services of the ThinkTank. The organization of the ThinkTank process is financed by the membership fee.

Our Service for Industrial Companies: We path your way to become a Smart Green Factroy!

In the ENERGY SAXONY ThinkTank, we take a holistic look at the measures to be taken in your company to increase energy and resource efficiency and reduce emissions, costs and waste in a panel of experts from research and industry. We network you with expert consultants, technology and service providers and identify suitable funding programs for you to finance the project. This is done in a structured, efficient and centrally coordinated process in which we accompany you from the very beginning.

Not only energy-intensive production companies, but also the sum total of small and medium-sized enterprises will become key players in a successful energy transition process by covering their energy needs themselves in the long term with renewably generated electricity at their own production sites and at the same time, contributing to balancing volatile electricity feed-ins by making loads more flexible. Industrial consumers thus become independent of fossil energy sources and can contribute to ensuring grid stability in the new energy system.

The global increase in demand for energy and raw materials and the associated price rises also call for a more efficient use of resources and productivity increases to ensure international competitiveness. This can be realized through the use of technology and the merger of companies into symbiotic alliances. The waste produced in the production process as well as surplus energy (electricity, heat, cooling) can then ideally be used as a resource by other industrial companies at low cost.

Via smart grids, digitalization enables an intelligent linking and joint control/regulation of decentralized electrical energy supply systems, of production processes (production technology, production and building infrastructure) to entire supply and value chains of an industrial operation. In addition, real-time data on energy and material flows can be collected by means of digital solutions and IoT applications and actively used to optimize energy use/costs in the sense of consumption optimization (load management).

Registration for a free consultation

Would you like to future-proof your production operations? Our experts from science and industry will show you how you can use technological solutions, digital innovations and cooperation approaches to significantly reduce energy and resource consumption, emissions and waste, and thus also your costs. You can register for a free consultation below. Mark Richter, Business Unit Manager Climate Neutral Factory Operation at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz and head of the ENERGY SAXONY working group Energy Efficient Production, will be happy to advise you personally on the individual options for implementing and optimizing sustainable energy supply systems and circular economy concepts at your production site. After your registration, we will be happy to contact you personally.

1st Call for Challenges in the #ENERGIETalk on 15.12.2021: Solution providers for the project "Plus-Energy-House historical foundry Chemnitz" wanted for joint project development! >>Video recording

2nd Call for Challenges: ThinkTank-Meeting on 12.05.2022: Joint development of solutions for the future vision of Schoeller Technocell GmbH & Co. KG: CO2-neutral paper production at the Weißenborn mill by 2045 I 08.07.2022 Production tour on site at Felix Schoeller Werk Weißenborn

Why everyone wins with the ENERGY SAXONY ThinkTank

With the joint development of solutions, developments can be advanced for the benefit of society and questions about the future can be answered. The ENERGY SAXONY Cluster Service creates win-win situations for all players involved, which are also accompanied by positive income effects:

Building sustainable regional value chains

If companies are supported in organizing their energy and material flows more efficiently and increasingly in accordance with the principle of a circular economy, while increasingly integrating renewable energies, more sustainable regional value chains will be created for the simultaneous benefit of the environment and the economy.

Securing a resource- and climate-friendly energy supply as a competitive advantage

The expansion of decentralized plants for the generation of energy from renewable sources on the premises of Saxon industrial companies can help to reduce import dependencies on fossil fuels for industry. The combination with energy storage and energy-flexible production ensures a sustainable energy supply for industry and offers the possibility to develop competitive advantages in the national and international environment.

Funding Support

Particularly for small and medium-sized industrial companies, the service offers valuable assistance in obtaining funding to implement technological innovations to reduce their energy consumption, emissions and resource use.

Science transfer

By involving scientific actors, a contribution is made to the transfer of science into concrete economic applications. Researchers are given the opportunity to test and optimize their developments in a practical environment.

Sales and economic promotion

The implementation of the concepts offers network players the opportunity to market their service and technology offerings and generate sales, which in turn strengthens Saxony as a business location overall.

Best practice examples to be copied

The implemented projects create real laboratories and best-practice examples that are disseminated to the outside world with media impact. This may also inspire other industrial companies to implement similar solutions in their own production halls.

Do you have any questions or suggestions?

We look forward to hearing from you and will be pleased to advise you in a consultation meeting.